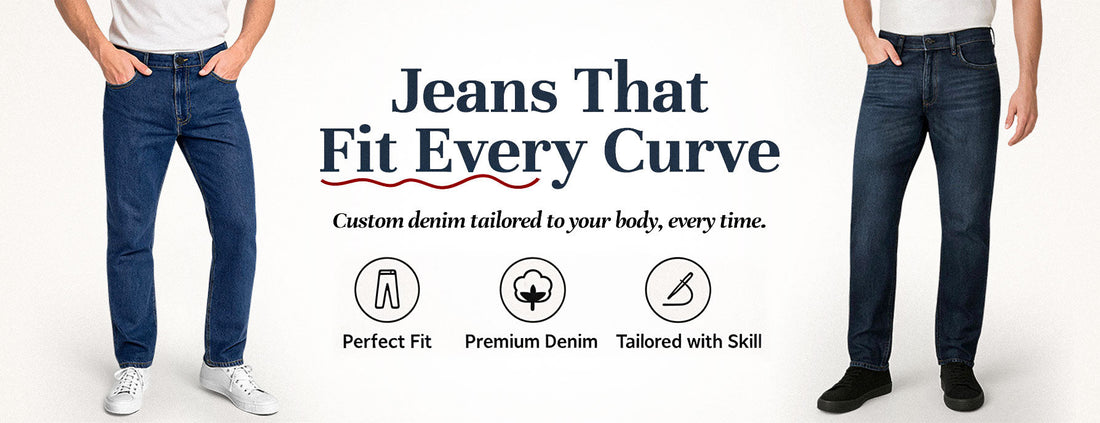

Custom jeans aren’t just about fashion—they’re about craftsmanship, precision, and individuality. Each pair is built from the ground up to reflect not only your measurements but your personal style and lifestyle.

So what exactly goes on behind the scenes? Let’s walk through the custom jeans process step-by-step and uncover how your one-of-a-kind denim is brought to life.

1. Consultation & Measurements

The journey begins with accurate body measurements. You may measure yourself at home using a tape measure or visit a local tailor for assistance. Key measurements include:

-

Waist

-

Hips

-

Inseam

-

Rise (front & back)

-

Thigh, knee, calf

-

Hem width

This foundation ensures your jeans fit like a second skin—no pinching, sagging, or awkward gaps.

2. Choosing the Denim Fabric

Next, you select the denim fabric that best suits your needs. Options include:

-

Selvedge: Durable, raw edge finish

-

Stretch: Flexible with elastane for movement

-

Raw denim: Deep indigo, unwashed for custom fades

-

Organic: Eco-friendly and chemical-free

You’ll also decide on weight (light, mid, or heavyweight), wash (dark, light, vintage), and texture (rigid or soft).

3. Customization & Style Options

This is where your creativity takes over. You can personalize nearly every design detail:

-

Fit (slim, straight, relaxed, bootcut)

-

Rise (low, mid, high)

-

Stitching color

-

Pocket style & placement

-

Button and rivet finish

-

Hem shape and length

-

Distressing, whiskering, or fade treatments (optional)

Every choice makes your jeans more “you.”

4. Pattern Drafting

Using your measurements and style choices, expert pattern makers create a custom blueprint for your jeans. Unlike standard sizes, this pattern is made specifically for your body.

This stage is crucial—it ensures that each denim panel aligns perfectly when sewn together.

5. Cutting the Fabric

With the pattern ready, your chosen denim is carefully cut piece by piece. Precision here is everything—a single miscut can affect the final fit. Skilled hands make sure every curve and line follows your body map.

6. Sewing & Assembly

Tailors now bring your jeans to life. Panels are stitched together using high-quality threads and time-tested techniques like:

-

Flat-felled seams for durability

-

Reinforced pockets for strength

-

Strong waistbands for structure

Each seam is double-checked for strength and alignment.

7. Finishing Touches

Final elements are added:

-

Buttons, rivets, and zippers

-

Embellishments or distressing (if requested)

-

Clean hem finish

-

Pressing and steaming

Before packaging, your jeans go through a thorough quality inspection.

8. Final Fitting or Delivery

Once complete, your jeans are either shipped directly to you or made available for final fitting. If anything feels off, many custom denim makers—like StudioSuits—offer free alterations to ensure the perfect finish.

Why Custom Jeans Matter

The beauty of the custom jeans process is that it blends old-world tailoring techniques with modern technology to create something truly unique.

-

No guesswork

-

No generic sizing

-

No mass production

Instead, you get craftsmanship, attention to detail, and a story stitched into every seam—your story.

Final Thoughts

Understanding how custom jeans are made gives you a new appreciation for every stitch. From initial measurements to the final button, each step is done with purpose. The result? Jeans that not only fit perfectly but feel like they were meant for you—and only you.

Explore Our Custom Jeans Collection

Design your next pair with StudioSuits and experience jeans made to fit your life, your style, and your body.

Start your custom denim journey today with our custom jeans process.